A multi-state system integrator cut new-part usage, increased returns compliance, and recovered value from used service parts through a controlled reverse logistics and refurbishment program.

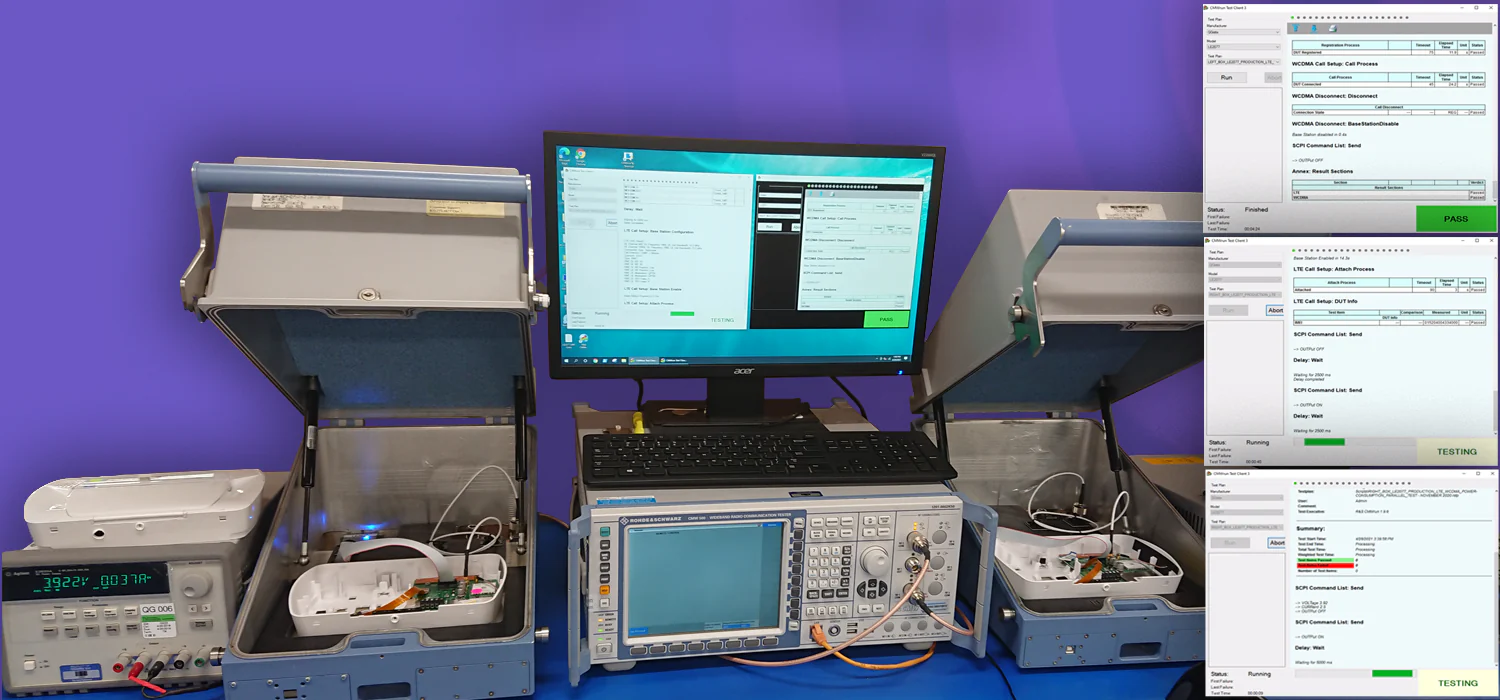

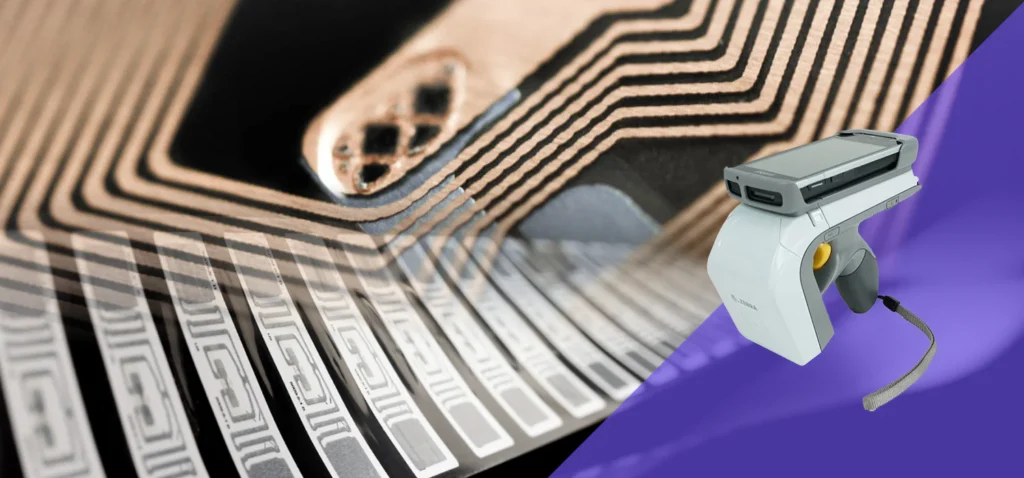

Green Wave Electronics cataloged every returned unit, matched it to field scans, refurbished the majority for redeployment, and routed in-warranty failures back to manufacturers for credits or replacements, reducing eWaste and financial risk.