A major clothing retailer needed to upgrade inventory control and loss-prevention across hundreds of stores without overnight multi-day installs or temporary closures.

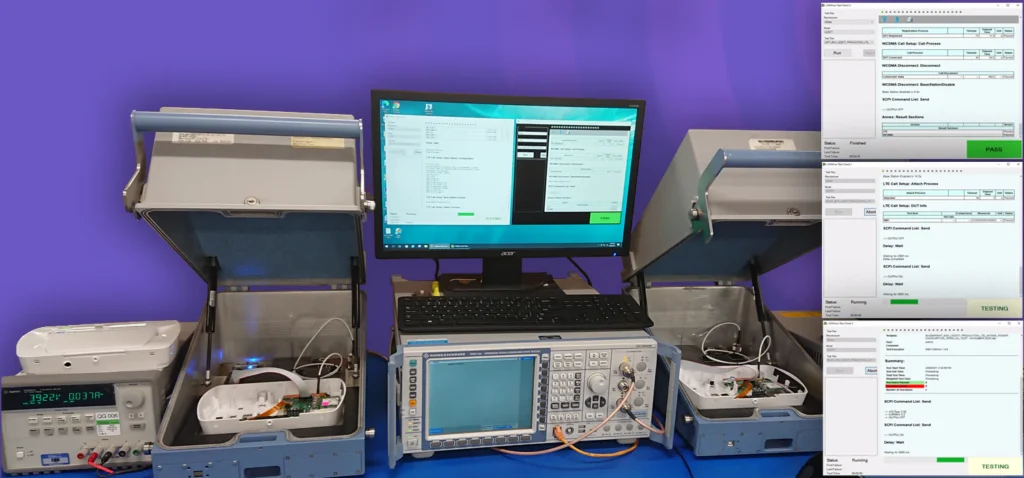

Green Wave Electronics pre-configured, fully tested, labeled, and kitted each store’s equipment, then shipped it as a single scheduled delivery for install day. Post-installation failures were covered via an Advanced Replacement Program with configured replacements shipped overnight.